What is Reverse Logistics? A Complete Guide

In today’s fast-paced e-commerce and manufacturing world, efficient supply chains no longer end at product delivery. Welcome to the era of reverse logistics — a crucial component that enhances customer satisfaction, sustainability, and profitability.In this comprehensive guide, we’ll explore what reverse logistics is, why it matters, how it works, and how businesses can leverage it for competitive advantage.

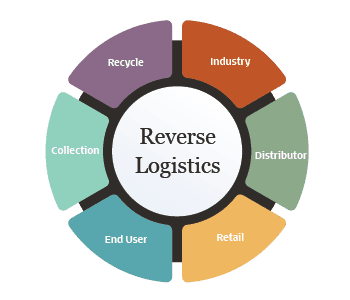

What is Reverse Logistics?

Reverse logistics refers to the process of moving goods from their final destination (the customer) back to the seller or manufacturer. This can be for returns, recycling, refurbishing, or proper disposal.Unlike traditional logistics, which focuses on getting a product to the customer, reverse logistics deals with managing product returns and post-sale activities effectively.

Why is Reverse Logistics Important?

Reverse logistics is vital for several reasons:- Customer Satisfaction: Easy and quick return policies improve customer trust.- Sustainability: Recycling and refurbishing reduce waste and environmental impact.- Cost Efficiency: Proper handling of returns saves costs on warehousing and restocking.- Brand Reputation: Green practices and efficient service build brand loyalty.

Key Processes in Reverse Logistics

Reverse logistics involves multiple steps depending on the product and industry. Common processes include:1. Product Returns: Products returned due to defects, damage, or customer dissatisfaction.2. Remanufacturing or Refurbishing: Returned goods that are repaired or upgraded and then resold or reused.3. Recycling and Waste Management: Disposing of or recycling products/materials responsibly.4. Asset Recovery: Recovering valuable parts or components from used products.5. Packaging Reuse: Collecting and reusing boxes, containers, or pallets to minimize waste.

Industries Using Reverse Logistics

- E-commerce: Return management and restocking.- Retail: Handling seasonal returns and excess inventory.Automotive: Refurbishing parts or collecting end-of-life vehicles.- Electronics: Recycling old devices and components.- Pharmaceuticals: Managing expired or unused medications.

Benefits of Reverse Logistics

- Reduced Costs: Efficient returns processing cuts transportation, labor, and inventory expenses.- Improved Sustainability: Recycling and reuse reduce landfill waste and carbon footprint.- Stronger Customer Relationships: Flexible and hassle-free return policies improve brand loyalty. - Inventory Optimization: Returned goods can be restocked or sold at discounts.

Common Challenges in Reverse Logistics

While the benefits are significant, businesses must also navigate several hurdles:- Complex Return Flows: Managing multiple return sources and conditions.- Lack of Visibility: Tracking returned goods efficiently- Increased Handling Costs: Sorting and inspecting returned items- Fraud Risks: Fake or unethical returns.- Limited Infrastructure: Absence of dedicated reverse logistics teams or systems.

Real-Life Example: Amazon’s Return Process

Amazon has built a powerful reverse logistics model by:- Offering simple return options.- Partnering with local drop-off points- Restocking or liquidating returned items.- Reselling refurbished items on Amazon Renewed.This not only boosts customer trust but also keeps operating costs in check.

Conclusion

Reverse logistics is no longer an afterthought — it’s a strategic necessity. Whether you’re running an e-commerce store, a manufacturing unit, or a retail chain, embracing reverse logistics can reduce costs, enhance sustainability, and deliver better customer experiences.Start planning your reverse logistics strategy today to stay ahead in the competitive supply chain landscape.